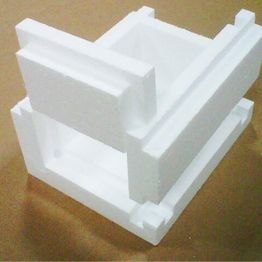

Robin II developed and now produces a unique cooler design—the Loc-R-Box—that requires no tooling, can be made to fit into any carton, with custom wall thicknesses. Designed and engineered to meet the demands of the refrigerated/frozen food industry and to combat the high costs of molding, these patent pending custom coolers have a unique interlocking system that makes the cooler perform the same as a molded cooler, but for a reduced cost. These coolers can be shipped to the customer flat, reducing air space in transport and allowing more of the boxes to be shipped. Made from virgin EPS in 1 to 2 pcf+ densities, these white interlocking sections of EPS can fit any carton size with any wall thickness desired and are subject only to customer specifications and customer testing protocols. In addition they are both recyclable and reusable. The Loc-R-Box production lead times are typically one to two weeks including delivery.

Robin II developed and now produces a unique cooler design—the Loc-R-Box—that requires no tooling, can be made to fit into any carton, with custom wall thicknesses. Designed and engineered to meet the demands of the refrigerated/frozen food industry and to combat the high costs of molding, these patent pending custom coolers have a unique interlocking system that makes the cooler perform the same as a molded cooler, but for a reduced cost. These coolers can be shipped to the customer flat, reducing air space in transport and allowing more of the boxes to be shipped. Made from virgin EPS in 1 to 2 pcf+ densities, these white interlocking sections of EPS can fit any carton size with any wall thickness desired and are subject only to customer specifications and customer testing protocols. In addition they are both recyclable and reusable. The Loc-R-Box production lead times are typically one to two weeks including delivery.

Leave behind the expense and hassles of shipping your products in molded EPS coolers. Contact Robin II today for further information.